Axle assemblies, comprising bearings, gears, and shafts, are crucial for vehicle motion and essential in Reconfigurable Ground Vehicles (RGVs) for diverse terrain navigation. RGV wheels, engineered with precision and high-quality materials, enhance traction, stability, and control in extreme conditions, offering a competitive edge in motorsports and off-road vehicles. These wheels optimize weight distribution, improve cornering, and provide a quieter ride. Axle assemblies are critical for high-performance vehicles, transmitting power while ensuring smooth rotation and efficient torque distribution. Regular maintenance is vital to prevent issues like misalignment, bearing failure, and broken axles. Future trends in axle technology include using advanced materials and integrating smart technologies for improved performance, fuel efficiency, and vehicle stability.

Axle assemblies are fundamental to vehicle motion, acting as the backbone that connects wheels to the drivetrain. This article delves into the intricate world of these components, exploring their various types, including high-performance RGV wheels. We dissect the essential components that make up an axle assembly and analyze how they contribute to vehicle handling and stability. Furthermore, we discuss common issues, maintenance tips, and future trends in axle technology, highlighting advancements aimed at enhancing performance and efficiency, particularly for RGVs.

- Understanding Axle Assemblies: The Backbone of Vehicle Motion

- RGV Wheels: A Closer Look at High-Performance Axles

- Components That Make Up an Axle Assembly

- How Axle Assemblies Contribute to Vehicle Handling and Stability

- Common Issues and Maintenance Tips for Axle Assemblies

- Future Trends in Axle Technology: Enhancing Performance and Efficiency

Understanding Axle Assemblies: The Backbone of Vehicle Motion

Axle assemblies are fundamental components in any vehicle, playing a pivotal role in enabling motion and connecting the wheels to the drivetrain. These assemblies consist of various parts, including bearings, gears, and shafts, meticulously engineered to work in harmony. Understanding their function is crucial when it comes to optimizing vehicle performance, especially for specialized vehicles like RGVs (Reconfigurable Ground Vehicles).

In the context of RGVs, axle assemblies must be robust yet adaptable to handle diverse terrain and mission requirements. They facilitate the vehicle’s ability to turn, steer, and maintain stability during complex maneuvers. By understanding the intricate details of these assemblies, engineers can enhance design choices, leading to improved mobility, efficiency, and overall performance in challenging environments.

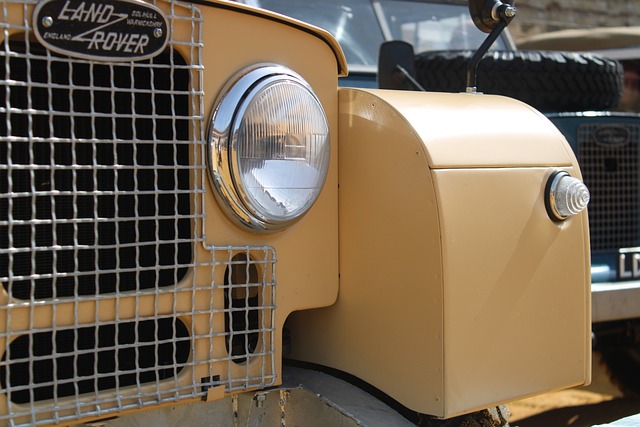

RGV Wheels: A Closer Look at High-Performance Axles

RGV Wheels, or high-performance axles, are a key component in the world of motorsports and off-road vehicles. These specialized wheels are designed to enhance vehicle dynamics by providing improved traction, stability, and control during extreme driving conditions. The RGV Wheel’s unique construction features robust materials and innovative engineering, enabling it to withstand rigorous demands while delivering exceptional performance.

The high-quality materials used in RGV Wheels ensure durability and strength, allowing them to maintain their integrity even under the most challenging circumstances. This focus on material science and precision manufacturing results in wheels that can handle intense forces and extreme terrain, providing drivers with a competitive edge. Additionally, the ergonomic design of RGV Wheels optimizes weight distribution, contributing to enhanced cornering capabilities and overall vehicle stability.

Components That Make Up an Axle Assembly

An axle assembly is a crucial component in any vehicle, connecting the wheels to the drivetrain and enabling smooth rotation. Its primary elements include the axles, which are sturdy rods that transfer power from the differential to the wheels, and rgv wheels (also known as hub assemblies), which house bearings, seals, and lubricants to support and facilitate wheel rotation. The differential, a vital part located at the end of the axle, plays a key role in allowing each wheel to rotate at slightly different speeds during turns, ensuring optimal traction and control.

These components work in harmony to provide stability, maneuverability, and safety on the road. RGV wheels, with their sophisticated bearing systems, ensure smooth and quiet operation, enhancing the overall driving experience. The intricate design of an axle assembly reflects the constant evolution of automotive technology, aiming to deliver improved performance, fuel efficiency, and reduced maintenance requirements.

How Axle Assemblies Contribute to Vehicle Handling and Stability

Axle assemblies play a pivotal role in vehicle handling and stability, especially when it comes to high-performance or off-road vehicles. These components are responsible for transmitting power from the engine to the wheels while ensuring smooth rotation and efficient torque distribution. In modern vehicles, especially those equipped with RGV (Recirculating Ball) wheels, axle assemblies must withstand extreme conditions, providing stability at high speeds and agility during turns.

The design of axle assemblies directly impacts how a vehicle responds to driver inputs. Well-engineered assemblies enable better weight transfer during cornering, allowing for enhanced traction and improved handling dynamics. This is particularly crucial in off-road scenarios where terrain variations demand robust stability and control. RGV wheels, with their advanced bearing systems, further contribute to reduced friction and increased durability, making axle assemblies an integral part of overall vehicle performance and safety.

Common Issues and Maintenance Tips for Axle Assemblies

Axle assemblies, including those that support RGV wheels, are critical components in any vehicle’s suspension system. Over time, they can face several common issues due to wear and tear, poor maintenance, or subpar installation. One of the most frequent problems is excessive play or misalignment, which can lead to uneven tire wear and reduced handling stability. Other issues include bearing failure, causing vibrations and noise, and broken axles, resulting in unsafe driving conditions. Regular maintenance is crucial to prevent these problems. Keeping axle assemblies lubricated with high-quality grease and inspecting them for signs of damage or corrosion can significantly extend their lifespan. Additionally, ensuring proper alignment and balancing of wheels and tires can help maintain optimal performance and prolong the life of the entire suspension system, including RGV wheels.

Future Trends in Axle Technology: Enhancing Performance and Efficiency

The future of axle technology promises significant advancements, focusing on enhancing performance and efficiency, particularly in industries like automotive and heavy machinery. One prominent trend is the integration of advanced materials and manufacturing processes to create lighter, yet stronger axles. This shift towards reduced weight can substantially improve fuel efficiency and handling dynamics for vehicles equipped with RGV (Reinforced Graphite Fiber) wheels, which are expected to gain popularity due to their exceptional strength-to-weight ratio.

Additionally, the adoption of smart technologies and sensors is on the rise, enabling real-time monitoring and adaptive control of axle systems. These innovations can optimize torque distribution, improve traction in challenging conditions, and enhance overall vehicle stability. Such advancements have the potential to revolutionize transportation efficiency, safety, and sustainability, especially with the growing demand for environmentally friendly and high-performance vehicles equipped with cutting-edge RGV wheels.

Axle assemblies, as demonstrated by the advancements in RGV wheels, continue to evolve, enhancing vehicle performance and efficiency. From high-performance components to innovative technology, these assemblies play a pivotal role in ensuring optimal handling and stability. Understanding their intricate design and addressing common issues through proper maintenance are key to maximizing their potential. As we look ahead, future trends in axle technology promise to further revolutionize the automotive landscape.